![]()

While makeup brushes have been around for as long as women have been trying to look pretty, Germans are often given credit for inventing the modern makeup brush. That’s because the invention and history of the makeup brush really really goes hand-in-hand with the invention of the mass-produced mirror.

While makeup brushes have been around for as long as women have been trying to look pretty, Germans are often given credit for inventing the modern makeup brush. That’s because the invention and history of the makeup brush really really goes hand-in-hand with the invention of the mass-produced mirror.

So My Brush Betty went out in search of some quality German makeup brushes to see how the business, and the brushes, have changed.

We came across Da Vinci brushes, which has been making brushes for more than a century, 124 years in fact. We found a business that was still going strong. Like many makeup brush manufacturers, Da Vinci also makes artist brushes for painters–the largest collection of artist brushes in the world actually.

We talked to Hans-Friedrich Defet, Owner of Da Vinci:

1. I understand your family has been in the business of making brushes for many years. When did they start making brushes and when did you start making cosmetic brushes, in addition to paint brushes?

Our company was founded around the year 1890 (to make paint brushes) and for about 30 years now we have manufactured cosmetic brushes. During the first two decades of this new product line especially Mrs. Marianne Defet has masterminded the various brush types and the particular “da Vinci” design, influencing with her ideas the whole trade and product design at least in Europe.

2. How similar are the operations to make cosmetic brushes to paint brushes?

The operations to make high-quality cosmetic and artist brushes are absolutely comparable, however, different materials are used for the manufacture of the brush-heads.

3. How have the materials used in cosmetic brushes changed over the years? Fiber? Glue? Handles?

Fibres: Due to the different demands with liquid make-up and as alternative for people who are allergic to animal hair or want to live vegan, “da Vinci” has developed synthetic fibre compositions, which perform very well and at the same time emulate high-quality natural hair in terms of softness and application result.

Based on our experiences we have had during long development processes and testing phases we are happy to present our customers the unique line “da Vinci” SYNIQUE.

These blusher and powder brushes of this line are made from so-called crimped fibres–in our opinion the natural hairs “state of the Art” at the moment.

The utilized natural hairs have not changed during the past 30 years. For especially soft applications we have developed over the years hair compositions, which are very skin-friendly and smooth.

4. You have an “eco-friendly factory” and promote the factory that your operations are 100% sweatshop free. How is that different from the way most makeup brushes are made today around the world?

We are producing all our cosmetic brush series in our own factory in Nuremberg, Germany, providing our workers with quality workplaces, which are spacious and light. Being a manufacturer and no dealer, we control and challenge all processes, improving them constantly.

5. I see that you use many kinds of hair, fibers and bristles. How has the acquisition of these materials changed over the years? I understand that getting a good supply of animal hair, particularly goat, may be getting more difficult as populations generally consume less goat meat? Is this true?

Because of long-standing contacts built over decades we have very good connections to our material suppliers. At the moment there are no problems in procuring Chinese mountain goat hair, as in these regions, we buy the hairs from, the rural traditions are unchanged.

6. Can you walk me through the general process of how a cosmetic brush is made – or provide an overview? How much does your method vary from other brush manufacturers, if you know?

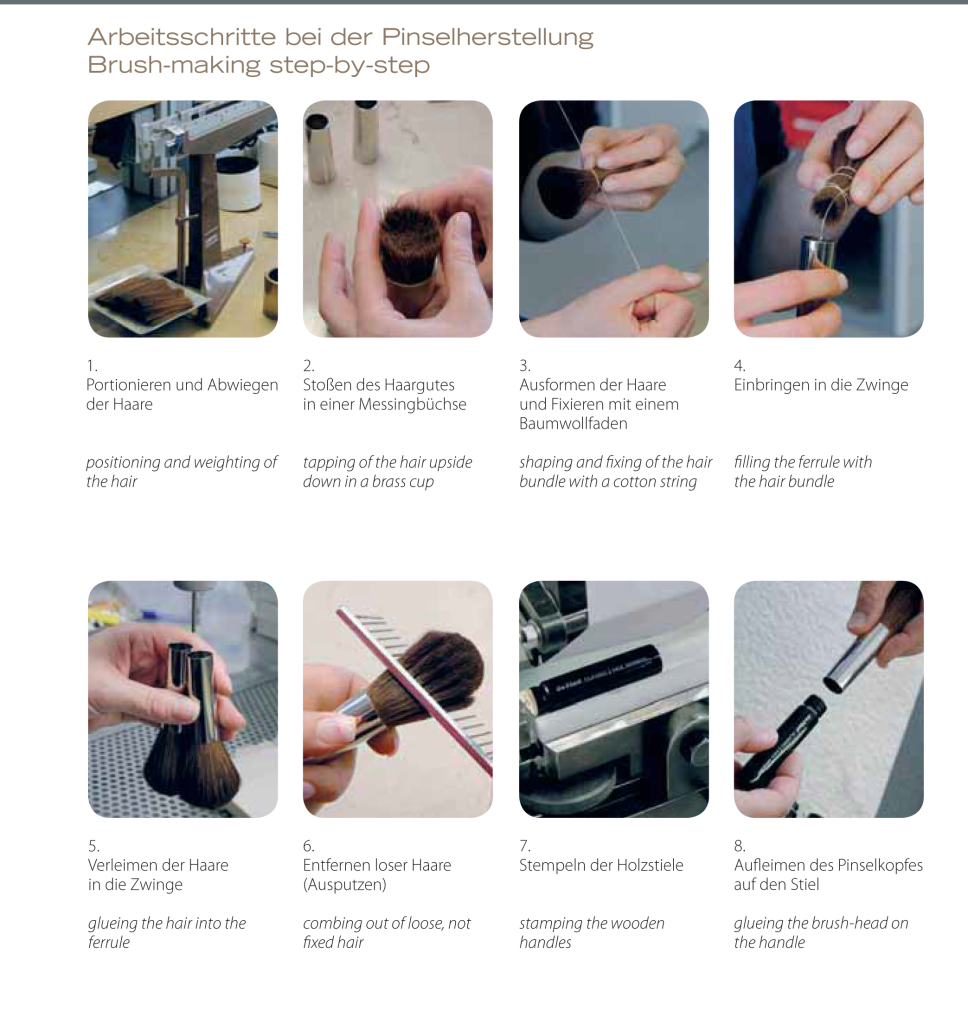

These are the processes of how a cosmetic brush is made:

a) quality control of the hair

b) portioning and weighing of the hair

c) tapping of the hair upside down in a brass cup

d) fixing with a cotton string and shaping of the hair

e) inserting the hair bundle into the ferrule

f) gluing the hair into the ferrule

g) combing out of loose, not fixed hair

h) stamping the wooden handles

i) gluing the brush-head on the handle

-> See also the attached page 3 of our catalogue

It takes around two days and six workers until one cosmetic brush is ready for shipment.

All our brushes are made by skilled brush-makers, who have served a three-year apprenticeship to be a professional brush-maker. They shape all brushes by hand, in order to maintain the natural hairtips.

This makes sure that the form of the brush is shaped ONLY by hand and not by cutting. So the consumer can rely on a brush that performs outstandingly well in terms of detail and area work.

7. How much automation is now used in brush manufacturing compared to the past and how do you see that changing in the future?

New production methods on in-house developed, half-automatic manufacturing machines and modern materials allow us to enlarge our assortment in the medium and lower price range (BASIC line, foundation and concealer brushes). But even for this young, modern line, we act on our proven maxim “Made in Germany”: Each brush is made in our own factory. All natural hair brushes are even “Handmade in Germany”.

8. How has Da Vinci remained competitive in this arena for so long, with so much brush manufacturing moving to Asia?

The main reason is the quality of the brush. On the market there are many different brush versions (type of hair, shape of the brush) meeting different demands. Whereas a “cheap purchase” may easily be an expensive experience: quick wearout, unsatisfactory make-up result and higher product consumption sum up quickly.

Therefore buying good tools is in our opinion always the best investment. High quality standards have always been of utmost importance for our complete assortment. Especially with cosmetic brushes we have observed during the last years, that the consumers pay more attention to purchase a functioning, enduring tool, which lasts for many years.

9. The economy has changed a great deal globally over the years, with many fluctuations. Do cosmetic brush sales tend to correspond to economic conditions or are they stable even through downturns?

Sales of our cosmetic brush assortment have continually risen, and we are optimistic that innovative and modern quality cosmetic brushes will always be a popular product, which will find its clientele also during economically difficult times.

10. It seems as though there is a lot of innovation in the area of cosmetic brushes. What does Da Vinci do to remain on top of trends?

On the basis of internal market researches and world-wide appreciated designs we are continually advancing our product assortment – in cooperation with internationally working make-up artists.

Thus our assortment stays always up-to-date and unique!

The vivid world-wide exchange of ideas with creative professional users will always be close to our heart, having always in mind to further improve the comfort of the user and the performance of the product – for the pleasure of our customers.

11. How do you forecast the Da Vinci brand performing in the future?

Being a quality manufacturer and “specialist for specialists” we do hope being able to continue the successful developments of our brand “da Vinci” – which is well-known among painting artists in more than 80 countries world-wide and to expand that positive development also to the cosmetic brush markets. Our international appearances on fairs like for example COSMOPROF show in Bologna and the World Bodypainting Festival in Austria, are continuously contributing to achieve this goal.

Hans-Friedrich Defet, Owner of Da Vinci. Mr. Defet was well educated in the traditions of brush making, learning from both his grandfather and father the history of brushmaking in Nuremberg, Germany.

VIDEOS

CONNECT WITH DA VINCI

Where to Buy Da Vinci Brushes in the US: